Sensor and Machine Data Acquisition

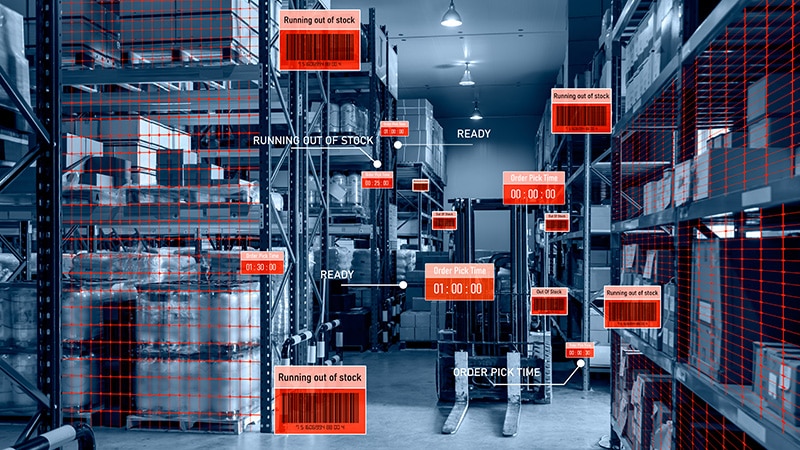

Improve Decision-Making with Greater Operational Visibility

A successful transition to Industry 4.0 relies on operational visibility gained from sensor and machine data. When correctly implemented, factory and warehouse data acquisition systems promise cost savings, improved predictive maintenance, and better optimization of processes.Connection’s Sensor and Machine Data Acquisition solutions help organizations securely integrate machines into modern enterprise IT and business intelligence systems. With our experience in both manufacturing and IT, we can help you standardize diverse machine outputs, including those from legacy processes. As a result, you’ll gain operational visibility and actionable analytics for clearer decision‑making.

Connection’s Sensor and Machine Data Acquisition solutions are designed to help organizations:

Ready to learn more about these offerings?

Call a Connection IT expert today: 1.800.800.0019

Manufacturing Expertise Meets IT Know-How

Connection’s manufacturing specialists understand the pressures and risks involved in manufacturing. We know how small margins for error can be, and how problems have to be solved within a limited number of cycles—often without aid from your IT team.We help manufacturers figure out how to solve their operational technology (OT) and IT problems every day. With our manufacturing technology expertise, Connection can provide right-fit sensor and machine data acquisition solutions for your organization. We work to connect your IT needs to your operational goals in line with regulatory, compliance, and business requirements. Additionally, we work to make sure tools integrate well, provide solutions that deliver and scale, and complement the balance of the enterprise.

Integration for Enhanced Intelligence

Factories and warehouses rarely standardize on a single operating system. Machines have long lifecycles and often lack network connectivity or modern standards to integrate data. It’s possible to connect these machines and standardize their outputs, but the complexity of managing data flows and integrating them into business applications and other operations platforms can negate whatever benefits you hoped to achieve.Connection’s expert guidance can provide clarity. First, Connection thoroughly assesses your existing manufacturing and IT infrastructure, as well as your operational goals. We consider your line-of-business (LoB) objectives and any potential implementation roadblocks. As a result, you’ll receive a data acquisition roadmap tailored to your specific processes, facilities, and business intelligence systems.

Connection’s services and solutions are offered a-la-carte. While we recommend implementing our Industrial Infrastructure solutions first, we are ready to support you no matter where you are in your industrial transformation (IX).

Manufacturing Videos

Smart Manufacturing Looks to the Cloud

Industrial Transformation Through Data and Edge Automation

Sensor and Machine Data Acquisition Solutions

|

Data AcquisitionMonitor production lines, improve predictive maintenance, adjust machinery for environmental factors, and more. Connection can help you identify potential industrial sensor implementation cases to reduce downtime and improve efficiency. |

|

Remote HMI and Machine ManagementRemotely monitor and control machine with HMI implementations. Connection can help you identify HMI use cases for your facility and assist with implementation across tablets and digital signage. |

|

Standards-Based Data IntegrationStandardize data to OPC UA and MQTT standards. Connection can help you connect legacy PLCs and other OT devices to IT infrastructure. Additionally, if needed, we can help you architect new integration solutions. |

|

Software and Business AnalyticsObtain actionable insights from your sensor and machine data. Connection can help you connect to cloud and on-premises business intelligence (BI) tools to process manufacturing data. |

|

AI and Machine LearningFully realize data-driven operations improvements with AI and ML solutions. Connection can help you identify AI and ML use cases in your facility to further improve process and personnel productivity. |

Connection Community

The Perfect Model of the World Is Here

For my senior design project in engineering school, we were asked to look at a new factory for a large... Read More

AI in Supply Chains: What Works, What’s...

Michael, a supply chain manager at a growing logistics firm, was staring down a nightmare. Warehouses were overflowing with the... Read More

Top Trends in Manufacturing Factory...

The manufacturing industry is undergoing a practical transformation—driven by the necessity for improved efficiency, enhanced security, and a future-ready infrastructure.... Read More

OT Cybersecurity Can No Longer Be Ignored

The threat of cyberattacks is escalating at a terrifying rate. A staggering 84% of businesses surveyed experienced at least one... Read More

TechSperience Episode 131: Securing Industry 4.0

The manufacturing sector is racing towards a digital future, but this innovation brings an explosion of cyber threats. This episode... Read More